Always Roll Perforated Window Vinyl Outwards

By Chris Toms, Owner & Project Manager, Outpacer

Here’s something we experienced lately, and thought I would share, in case other shops out there have experienced something similar. We recently had printed up around 200 square feet of perforated window vinyl for a storefront job. After printing and laminating, our production manager rolled up the films, labelled all of them neatly, and headed home for the day. He made one simple and honest mistake which caused us to have to reprint the entire batch of windows.

Rolling perforated window vinyl after production the correct way

Perforated window vinyl has a tendency to curl a particular way when it comes right off the roll. That’s why its important that you always roll up with the graphics facing outward. (Backing paper facing inwards). Rolling perforated window vinyl with the graphics facing inward can cause cavities between the film and the backing paper, and if left long enough (like shown below) you will end up with lamination separating from the perforated vinyl itself.

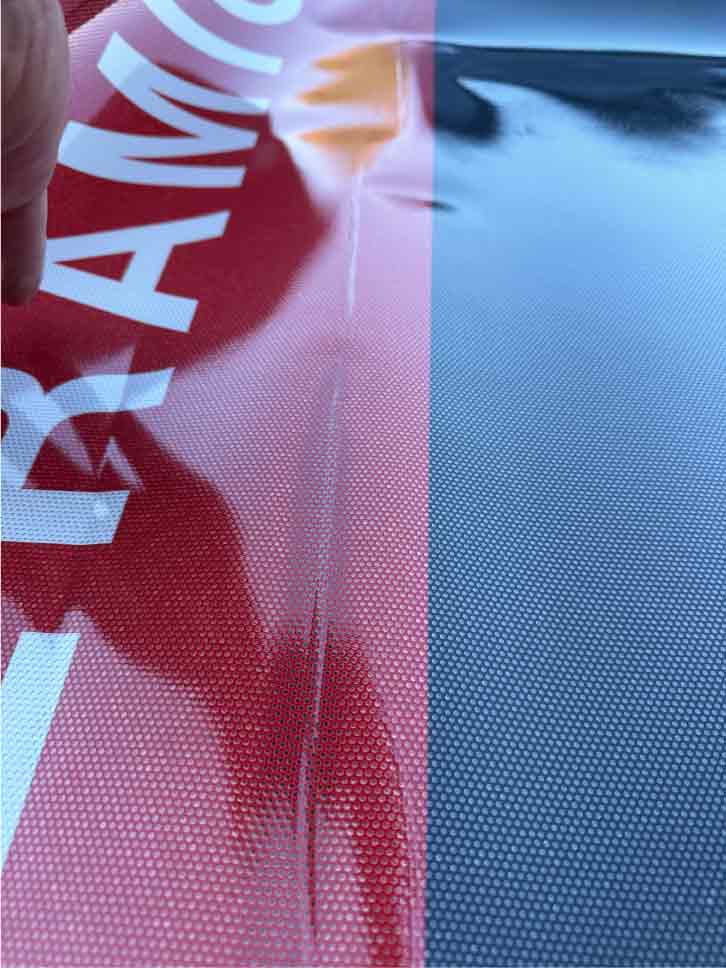

Example 1

Separation between the laminate layer and the perforated window vinyl

Example 2

Another example showing separation of the clear laminate from the printed vinyl

Example 3

How the perforated window vinyl appears after installation prompting removal

Avoiding laminate separation

Perforated window vinyl should always be rolled with the graphics facing outwards. This will keep the tension of the graphic across the media even and will prevent “fingers” and cavities from forming in the film. This applies to both laminated and non-laminated perforated window vinyl.

Below you can see the result of rolling perforated window vinyl the incorrect way (with the top of graphics facing inwards, ie. Backing paper outwards) which causes a failure between the media and the optically clear laminate.

From my experience, graphics rolled the correct way can be stored for quite a while before installation. Though in my experience, I prefer to keep the graphics flat if possible, as it makes for easier installation as the graphics are not holding a curled up shape in any particular way.

Vinyl storage best practices

Here we are using a high quality calendared perforated window vinyl rated for 3 years outdoor with a paired optically clear lamination. I have seen this happen with all grades of perforated window vinyl including cast vinyl. The best practice with all types of vinyl is to roll up graphics for storage with the graphics facing outwards. Graphics with masking, should be kept flat if possible.